Definition of Scheduling

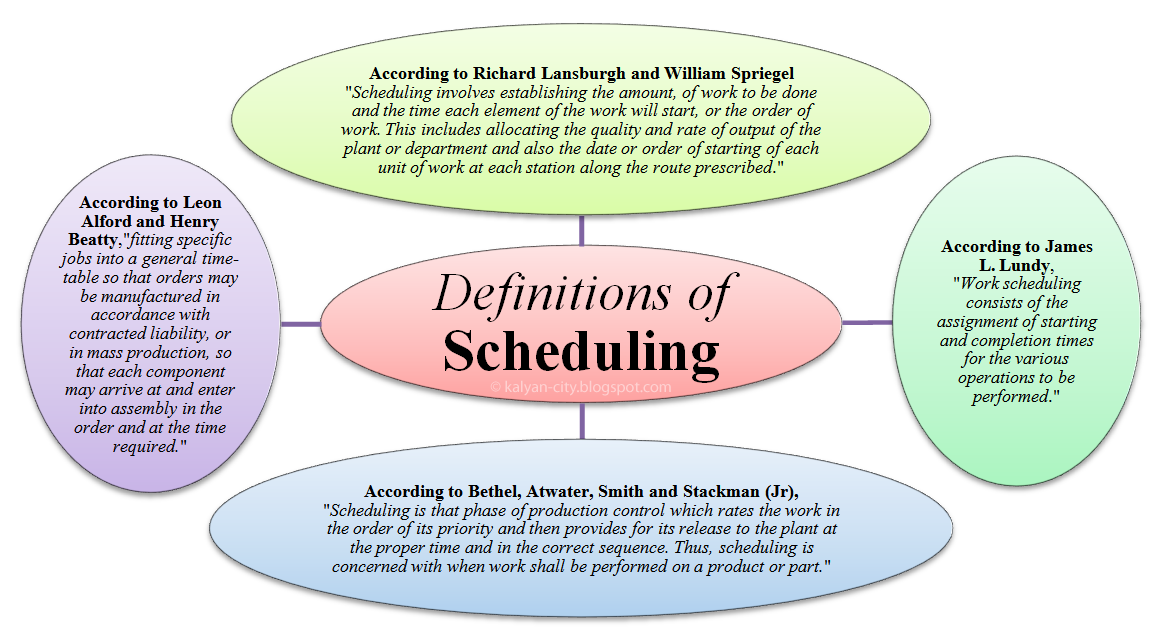

The definition of scheduling as quoted by an eminent scholar is as follows:

According to Richard Lansburgh and William Spriegel,

“Scheduling involves establishing the amount, of work to be done and the time each element of the work will start, or the order of work. This includes allocating the quality and rate of output of the plant or department and also the date or order of starting of each unit of work at each station along the route prescribed.”

Lansburgh and Spriegel gave scheduling definition in their book ‘Industrial Management’ published in 1995.

According to James L. Lundy,

“Scheduling consists of the assignment of starting and completion times for the various operations to be performed.”

James Lundy defined scheduling in his book ‘Effective Industrial Management,’ first published in 1957.

According to Bethel, Atwater, Smith and Stackman (Jr),

“Scheduling is that phase of production control which rates the work in the order of its priority and then provides for its release to the plant at the proper time and in the correct sequence. Thus, it is concerned with when work shall be performed on a product or part.”

This definition is referred from a book titled ‘Industrial Organization and Management,’ first published in 1945. This book is a collective work of Franklin S. Atwater, Lawrence L. Bethel, Harvey A. Stackman (Jr) and George H. E. Smith.

According to Leon Alford and Henry Beatty,

“Fitting specific jobs into a general time-table so that orders may be manufactured in accordance with contracted liability, or in mass production, so that each component may arrive at and enter into assembly in the order and at the time required.”

Alford and Beatty expressed above quote in their work titled ‘Principles of Industrial Management’ published in 1951.

Meaning of Scheduling

The meaning of scheduling can be grasped from the following points:

- Scheduling is the last step in production planning alone. However, it is the second step in production planning and control.

- It comes after routing. It is a time-table of production. It gives the starting and completion date and time for each operation of job (task or work). It is just like a railway time-table.

- The production process is divided into many different jobs. Scheduling arranges all these jobs in the order of priority. That is, it tells which job must be done first, which job must be done second and so on. Then it fixes starting and completion date and time for each job.

- It gives a lot of importance to the time element in the production process.

- It is also done for materials, parts, machines, etc.

The main purpose or objective of scheduling is to see that all production operations are completed in a given time. If the production is completed in an allotted time, only, then, the delivery of goods can be made on time. If this happens, it will increase the goodwill of the company.

The functions or procedure of scheduling is as follows:

- Make a list of all the production activities.

- Fix the starting time for each activity.

- Fix the finishing time for each activity.

- Prepare the time-table.

This article on scheduling is continued in the following post:

The kinds of scheduling are listed below:

- Master scheduling : The date of completion of production is assigned or fixed along with stage wise operation schedule.

- Operation scheduling : The time required to do some amount of work (task or job) with a given machine or process is fixed.

- Detail operation scheduling : First, all details necessary to do some amount of work with a given machine or process are identified. Later, time required to complete each detail operation of work is fixed.