Steps in Production Planning and Control

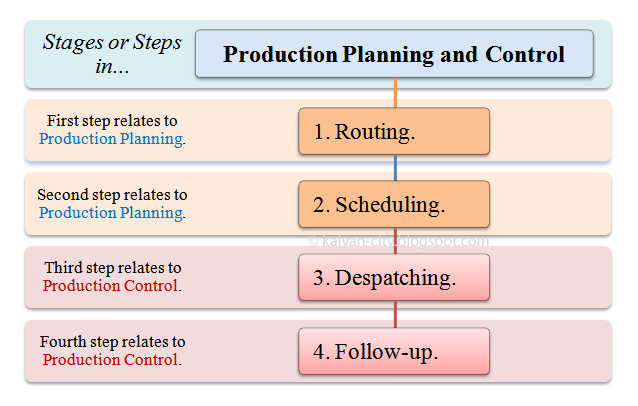

According to the British Standards Institute, there are four stages, steps, techniques or essentials in the process of production planning and control.

The four stages or steps in production planning and control are:

- Routing,

- Scheduling,

- Dispatching, and

- Follow-up.

Initial two steps i.e. Routing and Scheduling, relate to production planning.

Last two steps i.e. Dispatching and Follow-up, relate to production control.

Now let's continue our discussion further to understand each step in detail.

1. Routing

Routing is the first step in production planning and control.

Routing can be defined as the process of deciding the path (route) of work and the sequence of operations.

Routing fixes in advance:

- The quantity and quality of the product.

- The men, machines, materials, etc. to be used.

- The type, number and sequence of manufacturing operations, and

- The place of production.

In short, routing determines ‘What’, ‘How much’, ‘With which’, ‘How’ and ‘Where’ to produce.

Routing may be either very simple or complex. This depends upon the nature of production. In a continuous production, it is automatic, i.e. it is very simple. However, in a job order, it is very complex.

Routing is affected by the human factor. Therefore, it should recognize human needs, desires and expectations. It is also affected by plant-layout, characteristics of the equipment, etc.

The main objective of routing is to determine (fix) the best and cheapest sequence of operations and to ensure that this sequence is followed in the factory.

Routing gives a very systematic method of converting raw-materials into finished goods. It leads to smooth and efficient work. It leads to optimum utilization of resources; namely, men, machines, materials, etc. It leads to division of labor. It ensures a continuous flow of materials without any backtracking. It saves time and space. It makes the work easy for the production engineers and foremen. It has a great influence on design of factory's building and installed machines.

So, routing is an important step in production planning and control. Production planning starts with it.

Read article on procedure of routing in production.

2. Scheduling

Scheduling is the second step in production planning and control. It comes after routing.

Scheduling means to:

- Fix the amount of work to do.

- Arrange the different manufacturing operations in order of priority.

- Fix the starting and completing, date and time, for each operation.

Scheduling is also done for materials, parts, machines, etc. So, it is like a time-table of production. It is similar to the time-table, prepared by the railways.

Time element is given special importance in scheduling. There are different types of schedules; namely, Master schedule, Operation schedule and Daily schedule.

Scheduling helps to make optimum use of time. It sees that each piece of work is started and completed at a certain predetermined time. It helps to complete the job systematically and in time. It brings time coordination in production planning. All this helps to deliver the goods to the customers in time. It also eliminates the idle capacity. It keeps labor continuously employed.

So, scheduling is an important step in production planning and control. It is essential in a factory, where many products are produced at the same time.

3. Dispatching

Dispatching is the third step in production planning and control. It is the action, doing or implementation stage. It comes after routing and scheduling.

Dispatching means starting the process of production. It provides the necessary authority to start the work. It is based on route-sheets and schedule sheets.

Dispatching includes the following:

- Issue of materials, tools, fixtures, etc., which are necessary for actual production.

- Issue of orders, instructions, drawings, etc. for starting the work.

- Maintaining proper records of the starting and completing each job on time.

- Moving the work from one process to another as per the schedule.

- Starting the control procedure.

- Recording the idle time of machines.

Dispatching may be either centralized or decentralized:

- Under centralized dispatching, orders are issued directly by a centralized authority.

- Under decentralized dispatching, orders are issued by the concerned department.

4. Follow-up

Follow-up or Expediting is the last step in production planning and control. It is a controlling device. It is concerned with evaluation of the results.

Follow-up finds out and removes the defects, delays, limitations, bottlenecks, loopholes, etc. in the production process. It measures the actual performance and compares it to the expected performance. It maintains proper records of work, delays and bottlenecks. Such records are used in future to control production.

Follow-up is performed by ‘Expediters’ or ‘Stock Chasers’.

Follow-up is necessary when production decreases even when there is proper routing and scheduling. Production may be disturbed due to break-downs of machinery, failure of power, shortage of materials, strikes, absenteeism, etc.

Follow-up removes these difficulties and allows a smooth production.